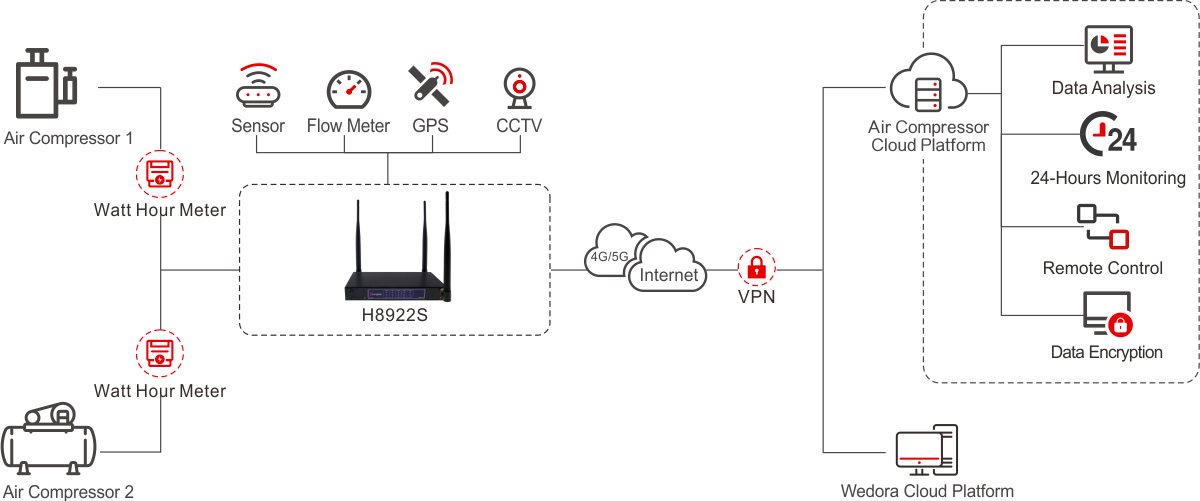

In recent years, air compressors have become indispensable power equipment in industrial plants. Large-scale air compressor stations usually have multiple sets of equipment to ensure the needs of different loads. Ensuring qualified air supply quality, meeting stable air supply pressure, and automatic adjustment of air supply flow are the basic tasks of air compressor station automation. With the continuous improvement of the level of automation, the requirement of building unmanned air compressor stations has become a development trend. Hongdian has rich experience in the field of industrial Internet of Things. Aiming at the Internet of things for air compressors, Hongdian has introduced energy-saving, intelligent, safe, remote monitoring, and fault warning air compressor system Internet of things solutions.